Understanding E-Axles: Drive, Regenerative, and Regulatory Challenges in Australia

E Axles

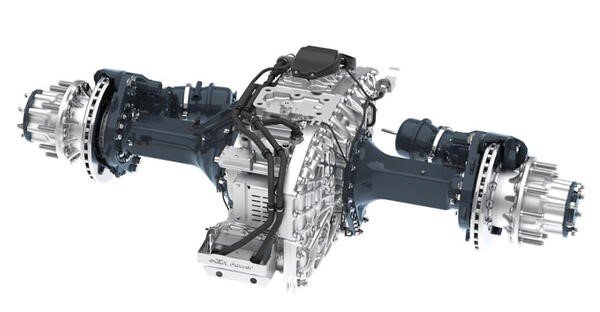

An e-axle integrates one or more electric motors; two- or three-speed reduction gearing and power-control electronics, into the centre of the axle. There are two different types of electric trailer axles: a drive and retarding type, similar to a truck e-axle; and the ‘recuperating’ type. This white paper explains both, plus where they are used and what’s allowed in the Australian market.

Drive and retarding e-axles

A drive e-axle is common on Battery Electric Vehicles (BEVs), where stored electrical energy is transferred to the motors on the axle which drive the axle. This setup replaces a propshaft in a truck for example, leading to higher torque and more efficient transfer of energy. They typically run at high voltages (>400v).

ADR restrictions currently prevent e-axles from being used to power the driveline, but they can be used to power fridge plants etc mounted on the trailer. The HVIA is currently working with road managers to allow field trials of powered trailers.

E Axle

Recuperating or regenerative e-axles

Regenerative e-axles work the opposite way to drive e-axles, in that they are able to generate electricity via braking or deceleration, which can then be used to recharge batteries. Some regenerative axles produce power in all forward motion, but this increases drag on the Prime Mover. These axles would most commonly be fitted to trailers.

Current Australian suppliers

SAF: Products: SAF-HOLLAND Australia

BPW: ePower: The generator axle that intelligently produces electricity while moving.

Dana (truck axle): Spicer® Electrified™ Zero-8 e-Axles - Dana Australia

VE Motion (startup e-trailer business): VE motion

Common terms

Motors types: E-axles use either synchronous or asynchronous motors, both offering distinct pros and cons. Synchronous motors are simpler, cheaper and run at a fixed speed. Asynchronous motors, on the other hand, are more complex but offer greater efficiency due to their variable speed. The simpler synchronous motors do generate drag, but the asynchronous don’t when not recuperating.

Number of motors: Single motor e-axles typically allow for a larger unit, but require a differential or geared drive to each hub. Dual-motor options, on the other hand, can be direct drive and are therefore more efficient. Both have their place, depending on packaging and energy requirements.

Drive style: E-axles are either direct drive or geared, and that usually comes down to whether they use a single electric motor or multiple units. A single motor solution requires a geared arrangement, which is less efficient due to losses in the gearbox and differential, but provides an opportunity for a larger motor to be packaged.

Cooling options: Much like engines and other mechanical systems, the option of air, oil or water cooling is available. While water cooling may improve durability and thermal efficiency, it weighs more and adds complexity to the system. Air-cooling on the other hand reduces cooling efficiency, which often requires a motor to run at a lower output. Of course, complex cooling systems also add to the cost of an e-axle.

Energy recuperation methods: Energy can be recuperated in a number of ways, but typically it is generated during braking or deceleration efforts. There are, however, e-axle options that generate electricity during all forward motion, which increases drag and requires more ‘energy in’, but suits scenarios where a vehicle maintains a constant speed for prolonged periods and isn’t operating in stop-start scenarios.

Recuperation ratings: The rate that the electric motor is rated to generate – ranging from 20kW right up to 80kW – is measured in kilowatts (kW). Rates higher than 20kW require brake blending in Europe, due to the strong braking forces generated.

E Axle